In the previous article we discussed in detail in which rocks the water is. Now we are going to design the structure of the water borehole.

Let’s look at our engineering calculations to design a water borehole based on your water needs, and still get the minimum cost of the borehole.

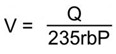

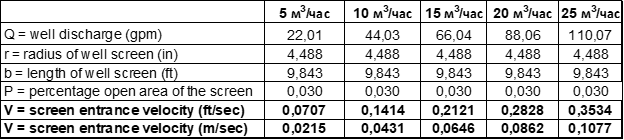

Let’s start with calculating the capacity of a four and five inch casing screens. Let’s calculate the screens productivity from five to twenty five cubic meters per hour. The length of the UPVC type filter pipe is three meters. The slot area of the total filter surface area is three percent. We determine the rate of water entry into the casing screens from the water layer according to the formula:

V = screen entrance velocity (ft/sec)

Q = well discharge (gpm)

r = radius of well screen (in)

b = length of well screen (ft)

P = percentage open area of the screen

Recommendations for maximum well entrance velocity range (Groundwater and Wells, Second Edition, Johnson Screens) to 1,5ft/sec = 0,457 m/sec (AWWA, 2015).

The Calculation of Yield for casing screens five inches (140 mm)

The resulting calculations can be seen in the table, we can see that the calculated input speed for the screen five inches within the acceptable values, it is less than the upper limit of one and a half feet per second, recommended by the standard.

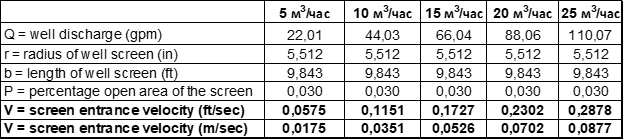

Next, we will compute the productivity for a four- inch screen (114 mm).

The designed inlet velocity is also less than the upper limit recommended by the standard for four-inch casings, up to twenty-five cubic meters per hour.

As we can see from the calculations, the usage of even one casing screen of three meters long provides the possibility of normal borehole operation with the yield of up to twenty-five cubic meters per hour. The thickness of water layers in Uganda is ten meters or more. So, it is possible to install three casing screens pipes of three meters long into the well with this thickness. Therefore, there will be a triple margin of the possible productivity of the borehole.

The most important parameters on which the cost of a borehole depends are its length and diameter. Justification of the minimum diameter of the casing screens, which ensures the design selection and the allowable reduction, allows to reduce the cost of the well, taking into account the fact that modern borehole pumps provide a wide range of capacities and pressures at a small outer diameter.

The cost of a borehole pump will also depend on several factors: the type of pump, the capacity and the diameter, and an increase in diameter will lead to a price increase.

Based on the criteria of water entry speed in the screen of 1.5 feet per second, we can recommend to use a four-inch column, for boreholes with a design capacity of up to 25 cubic meters per hour, which will provide the required productivity for many private boreholes in Uganda. The final decision should be made by taking into account the real hydrogeological conditions of the projected well.

An eye-opening example of pumping equipment for a four-inch borehole is a three-inch solar aquifer pump.

You can contact the office of a professional drilling company PAKAST TECHNICAL SERVICES to get more information about the cost of drilling boreholes with a four-inch casing running, and the cost of a three-inch pump of a solar water system.

The recommended minimum gap between the casing screens column and the borehole wall (annular space between the borehole well and casing) is one inch (Roscoe Moss Company, 1990, Handbook of Groundwater Development, John Wiley & Sons, Inc.). Accordingly, the diameter of the bit for drilling under the filter column four inches will be at least one hundred and sixty-five millimeters.