1. Solid mineral deposits exploration

There are many technologies for mineral deposits exploration. The application of each method depends on qualitative characteristics of the deposit, natural conditions and the landscape of the area. Notwithstanding the above factors, geological exploration is normally performed in six stages:

I. Geophysical and geological surveys

Prospective development areas with probable presence of minerals are determined at the stage of geophysical and geological surveys. Exploration works are started after thorough survey of the identified prospective areas.

II. Mineral deposits exploration

Specialists identify certain types of minerals in the course of exploration works. Mineral deposits exploration includes certain stages. The first general stage includes field boundaries delineation. After that, wells are drilled or mine working is performed for subsequent geological surveys. Geological survey results allow assessing fields’ potential. If the survey was successful, quantitative estimation of minerals is conducted.

III. Preliminary exploration

At the stage of preliminary exploration, not only quantitative, but also qualitative characteristics of fields and mode of their occurrence are determined more accurately than at previous stages. At this stage, wells are also drilled or mine working is performed for sampling.

IV. Detailed exploration

This stage of geological exploration is started only if the industrial and economic feasibility of field development is proven. Detailed exploration results in obtaining studymaterials required for commercial operation of the deposit. These materials must comply with the requirements for “exploration maturity of the study area, in accordance with the classification of reserves and forecast resources”

Table of Contents

V.Appraisal

Field appraisal is conducted if there are areas that were insufficiently studied at the above-mentioned stages. Appraisal is carried out to estimate newly discovered reserves or to transfer the resources to higher categories. “In the meantime deep mines are built for both exploration and production-exploration purposes.”

VI. Exploration appraisal.

Exploration appraisal is conducted simultaneously with drilling penetration works in order to prepare workings for production and to specify quantitative and qualitative data on the developed field. The main production method of this type of works is drilling penetration of vertical, horizontal and inclined workings.

2. Geological exploration methods

The direction, boundaries and nature of exploration works are determined mainly by the topographic features, soil properties and the presence of groundwater. All these conditions can be determined through geological survey, which serves as the basis for prospecting works.

However, even the most favorable forecasts do not allow making solid conclusions about the feasibility of developing deposits in a particular area and do not provide data on exact location of deposits.

In the exploration of ore deposits, geologists aim to find direct signs of certain type of minerals in the investigated area in order to obtain comprehensive information. Such signs may include “increased concentration of a useful chemical element in sediments covering a deposit, mineral fragments, oxidation or leaching zone at the outlet of minerals on the surface.”

It can be concluded that the main task of geological exploration is to detect “direct manifestations of mineralization or direct signs of minerals.”

There is a large number of methods for conducting exploration works. Their choice directly depends on the specifics and geological structure of the studied area.

2.1. Geological survey method

The main method used in the exploration of ore deposits is geological survey. The rest of methods are used to detail and refine the data obtained using geological survey.

During the survey, geologists analyze almost all outcrops in the studied area. At the same time, increased attention is paid to areas where the occurrence of minerals is most likely. In the event of insufficient information about a particular area, surface sampling is performed.

2.2. Aerogeological survey method

Aerogeological survey is the most effective method in conditions of inaccessibility of many potentially attractive territories for exploration.

This method allows obtaining the most complete understanding of geological features of the studied areas in combination with ground survey. The aerial photo base allows conducting a detailed study of all the features of the geological structure of the studied area, the presence of reservoirs, ravines, fractures, soil features, the area of occurrence of minerals and their qualitative composition.

2.3. Clastic method

The essence of clastic method is to detect fragments of minerals near rivers, streams, ravines and talus. Geologists find primary deposits based on the fragments found. The complexity of the method lies in the need to study all lateral tributaries and ravines, which complicates the search. Moreover, this method is very imprecise and requires additional exploration works.

2.4. Boulder-glacial method

The boulder-glacial method is inherently similar to the clastic method. It is mainly used in areas that were hidden under glaciers in the past geological era. The use of this method involves study of the movements of ancient glaciers. As a result of studies, geologists determine possible displacement of a mineral boulder. When several boulders located at a considerable distance from each other are found, it is often possible to determine the scattering fan, the “point” of which is the primary deposit. The search area can be narrowed by this method for application of more accurate methods in order to clarify the data on mineral deposits.

2.5. Heavy mineral concentration method

Heavy mineral concentration is obtained as a result of merging excess water with clay particles and lighter minerals after shaking the material sample.

Heavy mineral concentration method like the boulder-glacial method is similar to clastic method in methodology. Using this method, geologists investigate the sandy-clay mixture that is carried by streams and rivers, and can also be found on mountain slopes. Specialists can draw conclusions about the area where the primary deposit is located by studying the minerals in heavy mineral concentration.

2.6. Metallometric survey method

In areas where the deposit comes to the surface, minerals are often dispersed as a result of chemical leaching by ground and surface waters, as well as destruction of the place of occurrence of deposits and the formation of small fragments of ore. This fact is the basis for application of the metallometric survey method. Using this study method, geologists take samples of deluvium to determine the qualitative composition of minerals.

It must be borne in mind that plants absorb chemical elements from the soil. In this regard, sometimes more detailed information can be obtained by taking samples from plant ash in the study area.

2.7. Geochemical method

The geochemical method provides information on how chemical elements are distributed, moved and merged with each other. The main goal of this method is to establish the quantitative ratio of chemical elements of the studied deposit, the features of their dispersion and movement. The study results are presented in geochemical maps, which clearly indicate the distribution areas of chemical elements.

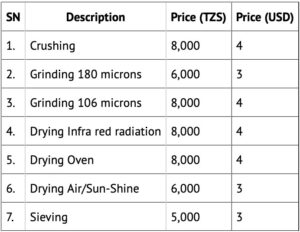

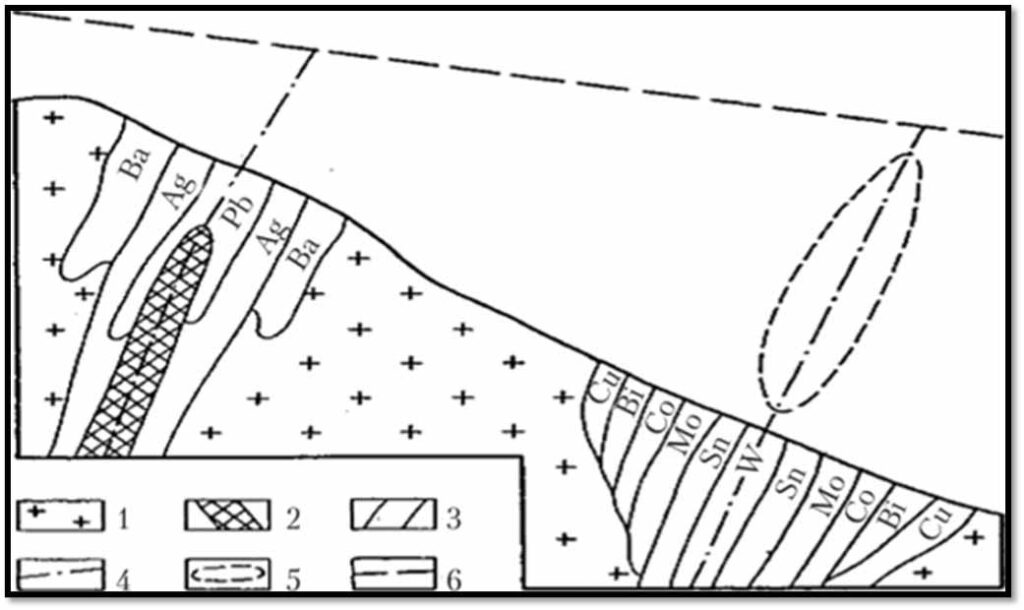

Figure 1. Model of geochemical zoning of primary dispersion halos (section): 1 – granites, granodiorites; 2 – ore body; 3 – primary scattering halos (supra-ore – Pb, Ag, Ba, sub-ore – W, Sn, Mo, Co, Bi, Cu); 4 – tectonic zone of crushing, coinciding with the axis of the ore body; 5 – eroded ore body; 6 – paleorelief line.

Figure 1.

2.8. Surface sampling method

Once the promising development areas have been identified using the above methods of geological exploration, geologists use the method of surface sampling. This method is usually final. It is used to search for concealed outcrops of deposits. The surface sampling method is labor intensive and costly. The characteristic feature of the method is the fact that work is carried out not over the entire territory of possible minerals occurrence, but only in those areas where their discovery is most likely and confirmed using simpler and cheaper methods.

2.9. Geophysical methods

The physical properties of surrounding formations are usually different from physical properties of minerals. Geophysical study methods are based on this fact.

Thus, ore can have magnetic properties (magnetic iron ore), high electric conductivity (pyrite ores), or can contribute to the emergence of natural electric currents due to oxidation on the surface. Mass accumulations of minerals with high specific gravity cause increased acceleration of gravity, and accumulations of light masses decrease gravity. There are ore bodies that can change the speed of seismic waves or reflect them.

Consequently, deviations in physical properties from standard rock properties can be observed in areas with mineral deposits. Such deviations are called anomalies.

The use of special devices measuring magnetic properties, electric conductivity, acceleration of gravity, the speed of seismic waves passage and other physical quantities, allows specialists to identify anomalies, and the latter can be used to identify the mineral bodies that caused the anomaly. Outcropping of the ore body to the surface is not necessary at all for formation of an anomaly, which can be detected by geophysical instruments. The influence on the readings of instruments for measuring the physical properties of deposits will be exerted by rocks hidden by sediments and occurring at a relatively shallow depth. This means that geophysical methods allow exploring minerals, the bodies of which are not outcropped on the surface, and, as a result, cannot be detected by other methods.

Hidden deposits can be discovered by drilling wells or developing deep mine workings. However, as a rule, the exact location and depth of deposits are unknown. Therefore, it is necessary to carry out a huge amount of drilling and mine working to obtain information about the deposits. Such works are labor-intensive and costly. The cost and labor intensity of anomaly detection study is much lower. These studies allow outlining limited areas of the territory where drilling and mine working are advised. This approach significantly reduces exploration cost. This is the main advantage of geophysical survey methods.

The main geophysical survey methods for mineral exploration: Gravimetry – the method based on measuring the acceleration of gravity using pendulum or torsion balance (variometer). Magnetometry is the method based on measuring the magnetic field and its disturbances using a magnetometer and magnetic balance. Electrometry (electrical prospecting) is based on several methods of measuring electrical and electromagnetic artificial and natural fields.

In practice, only one survey method is seldom used. More often, several methods are used in combination, and the most suitable methods are selected for specific conditions, thus ensuring the best effect.

2.10. Geophysical survey using magnetometer

“Magnetometric or magnetic survey (magnetic prospecting) is a geophysical method for addressing geological issues based on the study of the Earth’s magnetic field.”

Magnetic prospecting has the highest efficiency in comparison with other geophysical study methods. It is often used not only for mineral deposits exploration, but also for drawing up various maps and conducting structural studies.

The possibility of using this method is due to the content of minerals with ferromagnetic properties in the ores as impurities. Also, the ores themselves often have increased magnetic susceptibility.

Determination of magnetic field parameters in ore deposits and identification of magnetic anomalies by such characteristics as shape, depth, magnetic susceptibility, etc. is the main task of magnetic prospecting. Yet, there is also an inverse problem – quantitative estimation of the same parameters to the known distribution of the values of one or several elements of the Earth’s magnetic field.

Magnetic survey results interpretation contains closely related geophysical and geological clarifications. At the initial stage, the qualitative characteristics of the magnetic field anomalies are analyzed, which allows drawing conclusions about the position of certain geological elements, and the known facts about the magnetic properties of rocks allow establishing their nature. At the next stage quantitative characteristics of the field are evaluated.

3.Advanced methods of geological exploration

3.1. Aerogeophysical technologies

The use of a set of remote methods for measuring the magnetic field using aircrafts allows geologists to carry out magnetic prospecting in a short time and with high accuracy rates of fields that are promising for development and are in hard-to-reсover conditions.

The distinctive feature of aerogeophysical exploration is the ability to use complex geophysical methods for remote sensing. Moreover, the data obtained have high statistic accuracy. The accuracy of designed and altitude-related binding of measurement results is ensured by the use of satellite navigation systems.

It is worth noting high operation cost of the carriers of geophysical platforms (MI-8, KAA-226 helicopters, AN-24, AN, -26, AN-30, TU-204-330 aircrafts, etc.), complexity of attracting aviation infrastructure, presence or construction of special take-off and landing sites in study areas and, as a result, limiting the access of a wide range of researchers to this technology.

A very broad view of the studied area can be considered as a significant drawback of aeromagnetic survey method. In ground and aerial photography, the same types of magnetometers are used with limited measurement frequency: 20 times per second. In this case, “the distance between the measurement points is as many times greater as the speed of movement of the sensor on the plane rather than the speed of movement of the pedestrian”. Yet, upon measurement of magnetic fields from a bird’s eye view, geologists are faced with the problem of overlapping magnetic fields from all bodies on top of each other. Therefore, as a result of such measurements, the magnetic field map reflects only large objects, has low definition and looks “smeared”. In a word, we can summarize as follows: the higher the aerial survey is made, the less detailed is the magnetic field map.

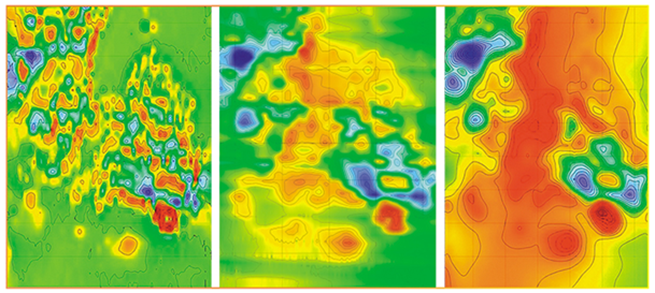

Maps of abnormal magnetic field obtained during walking (on the left), using UAV (in the center) and during aerial photography (on the right).

3.2. Aeromagnetic survey from UAV

The use of unmanned aerial vehicles (UAVs) for performing aeromagnetic surveys results in significant cost reduction of geological exploration (especially at the initial stages), reduction in the time required to perform works, and allows obtaining better and more complete data.

As a result of the survey carried out using UAV, geologists obtain accurate data on the features of the studied area. There are many tools that can be used to build a digital surface model, orthophotomaps, 3D models.

It takes about 15 minutes to shoot one object using a quadrocopter. In this case, a model can be built directly upon the survey completion. Data processing also does not take much time and lasts about 1.5 hours. The specialist only needs to upload the obtained images into a specialized program. The software allows automatic building of a 3D model based on specified coordinates.

Exploration of deposits from high altitudes is the main task of aerial-geophysical complexes. Quadrocopters are primarily used to assess the volume of minerals.

The use of drones for geological exploration significantly reduces the cost of exploration process compared to drilling or seismic methods. It is important to keep in mind that the use of UAVs for field exploration is not a licensed activity and can be used at the preliminary stage. This allows mineral companies to make a decision on the feasibility of developing a particular deposit.

It must be remembered that geological exploration is normally carried out in hard-to-reach areas with severe climate and natural conditions. However, these areas are currently the most interesting from the point of view of field exploration. In this regard, the above method is very labor-intensive and expensive.

The use of UAVs in combination with geophysical equipment helps to integrate the advantages of ground-based geological prospecting methods with remote methods. A quadrocopter can make surveys from different elevations. At the same time, extremely low heights are not a limiting factor for a quadrocopter; therefore, it is possible to conduct surveys with relief bending. The drone, based on satellite data, is able to independently determine the coordinates of measurement points.

The use of aeromagnetic survey technology from UAVs allows to significantly reduce the labor intensity and costs for mineral exploration without compromising the quality of measuring magnetic fields in the studied areas. Comparison of aeromagnetic survey performance using various methods is presented in Table 1 and Figure 4.

Table 1. Comparison of various aerial survey methods

Parameter | Surface survey | UAV survey | Big aviation |

Maximum scope of work | little | medium-much | much |

Minimum scope of work | any | little | huge |

Cost of work | expensive | low | expensive-medium |

Accuracy | low, high susceptibility to noise | high-precision, precise | medium, complex interference compensation |

Productivity (km / day) | average 15 | up to 220 | up to 1000 |

Preparation for work | complex | simple | difficult / expensive |

Human factor | high probability of error | n/a | average error probability, risk of the crew’s life safety |

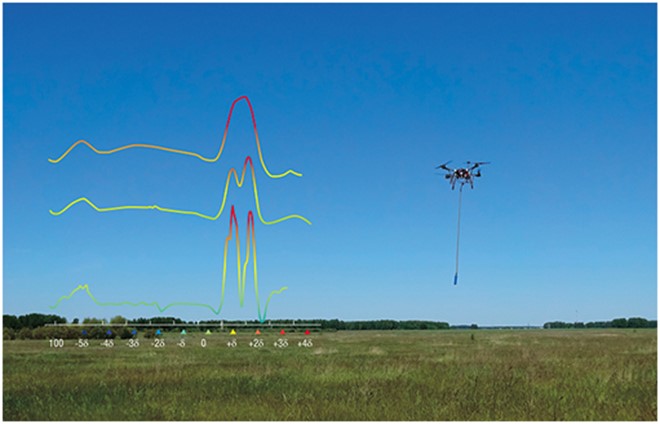

Figure 4. Comparison of abnormal magnetic field recorded during aerial survey, drone survey and surface profile survey. The schedule indicates that drone and surface survey recorded two narrow anomalies, which merged into one on the map obtained from the aircraft.

The use of UAVs for conducting magnetometric surveys has a number of important advantages:

- ability to carry out 12-16 flights daily and survey about 200 running kilometers of the territory, which is ensured by the ease of replacing the accumulator batteries;

- high accuracy of measurements regardless of surface features;

- visual result, provided by the possibility of building 3D field models, significantly increases the degree of work efficiency;

- topographic and vegetation specifics are taken into account for building the route, which can significantly reduce or eliminate the likelihood of equipment damage;

- the survey is performed more smoothly and at some distance from the ground surface, which significantly reduces the degree of influence of highly magnetic near-surface objects on the accuracy of the data obtained (Fig. 5);

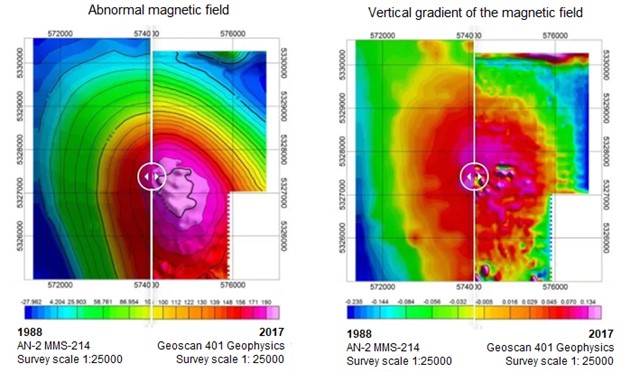

To analyze the results obtained using various methods, geophysical survey was carried out using MMC-214 quantum magnetometer with aviation (Scale 1: 25000) and Geoscan 401 Geophysical complex, where UAV was used as a carrier (Scale 1:10000) (Figure 5).

Figure 5. Comparison of geophysical survey results

The figure clearly indicates that using UAV systems results in obtaining a more detailed and clear map of the magnetic field than when using a large aircraft. Such results can be achieved by reducing the shooting speed and decreasing the flight altitude.

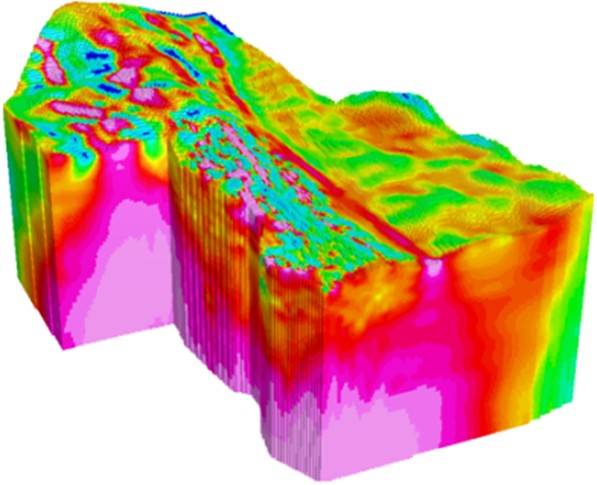

The possibility of presenting the results of aeromagnetic surveys using UAV complexes in the form of a 3D model allows to visually observe the geological structure of the studied area, to differentiate various geological structures according to the degree of their magnetization, to determine the size of the ore body with high accuracy and to estimate its quantitative characteristics (Figure 6).

Figure 6. 3D Model

Multiple investigations are conducted in the area with perspective minerals o obtain the necessary information about the investigated field. In this case, magnetometry is carried out from different elevations. Obviously, in this case, the application of the multilevel aeromagnetometry method using a drone as equipment carrier significantly speeds up and reduces the cost of the process (Figure 6).

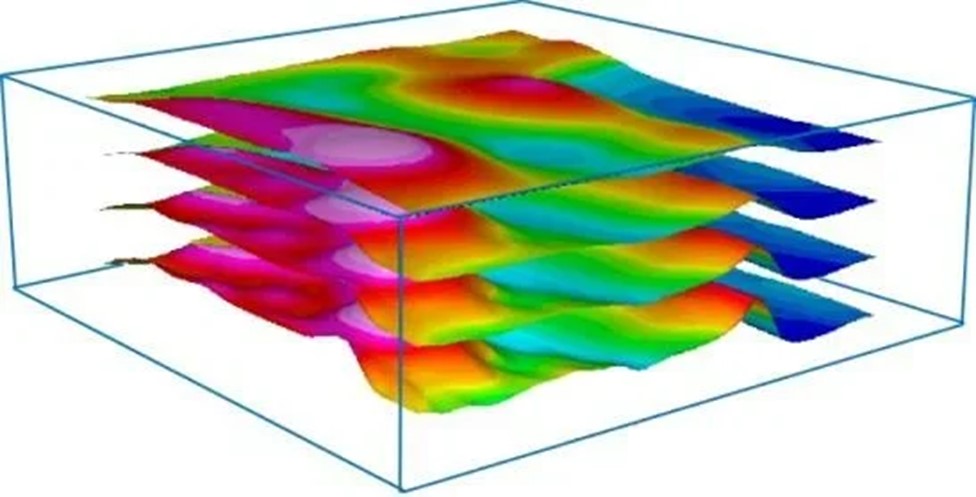

As a result of applying this method with the help of special software, it is possible to build a multilevel model of the magnetic field. Such a model is slightly similar with the result of an MRI scan and ensures a high degree of accuracy to determine the qualitative and quantitative characteristics of hidden deposits, their shape and position in space.

Figure 7. Multilevel model

UAV systems provide new opportunities for us to investigate hidden deposits. One of the most promising and fundamentally new areas is geomagnetic tomography. This method is based on the ability to conduct a magnetic survey of the same territory at different elevations relative to the earth’s surface. This allows performing detailed analysis of magnetic fields in upper (above ground) and lower (underground) half-spaces and to reconstruct them. “As a result, it is possible to present a picture of the magnetic field in full “volume” including abnormal areas. This approach allows to significantly improve the accuracy of geomagnetic data interpretation”.

Today, unmanned technologies are no longer a fantasy. They have firmly penetrated our life. They are explicitly often used in cases when it is necessary to conduct surveys of specifically large areas with complex topography in a fairly short time. The use of UAVs allows producer companies to save not only time, but also large financial costs.

Until recently, helicopter technology had to be used to carry out aeromagnetic work in hard-to-reach areas, which significantly increased the cost of geophysical survey.

Aeromagnetic survey from a quadrocopter is suitable for the most remote and inaccessible areas and is indispensable when there is a strong difference in elevation or boggy areas.

The cost of aeromagnetic survey from a quadrocopter will be…. dollars per one running kilometer, excluding the cost of personnel and equipment mobilization, accommodation and obtaining permits.

4. Well drilling methods

4.1. Preliminary exploration – Сore Hammer method

Pakast Technical Services also offers specialist engineering services to deliver innovative solutions to the most technical drilling challenges in some of the most complex operating environments in Uganda, Tanzania, Kenya. We offer a complete suite of specialized drilling services to meet the needs of our clients, to optimize the outcomes of their drilling programs, and to support them in complex drilling projects that occur throughout the resources lifecycle.

Pakast Technical Services Company uses air hammer, a set of technical means for core drilling, which allows drilling preliminary exploration wells on mineral deposits.

At present, impact-rotational drilling of the pneumatic hammer is becoming increasingly widespread for geological exploration of hard and strong rocks.

If you are just starting your exploration project in Africa, we will reduce your costs for exploration wells using the core hammer method.

4.2. Detailed exploration -– diamond drilling or RC drilling (reverse circulation).

Mineral Exploration – Diamond drilling

Diamond Core drilling involves using a hollow drill bit that has been impregnated with an industrial-grade diamond crown to cut a cylindrical core through solid rock. As the drill bit penetrates rock, the core is extracted in a solid cylinder and is winched to the surface through the centre of the drill rod in complete sections. This produces a rock sample that can be analyzed for mineral content and shows the structure of the cored interval.

We have the tools and capability to ensure that your contract is completed on time and meets the budget. Our trusted network of external resources can also be called upon to assist with specialized requirements when necessary.

Mineral Exploration – Reverse Circulation

To accomplish drilling project objectives within the budget, Reverse Circulation drilling offers a more cost effective drilling method for assaying chip samples and getting preliminary geological data prior to investing in detailed geological data from an exploration coring program. Reverse Circulation drilling is primarily used for exploration and grade control and can penetrate hard rock to depths of around 500 meters. Reverse circulation is also faster than coring which means more holes drilled.

PAKAST offers Reverse Circulation capabilities through our multi-purpose specialist rigs.

5.Laboratory for the study of mineral raw materials

Geological survey of Tanzania

Geological Survey of Tanzania (GST) was established as a Government Executive Agency in October 2005 under The Executive Agency Act No. 30, [CAP 245] of 1997, Establishment Order, 2005, Government Notice No. 418 published on 9/12/2005.

In July 2017, the Government of Tanzania amended the Mining Act of 2010 through the Written Laws (Miscellaneous Amendments) Act, No. 7 of 2017. Through the amendment, new functions were initiated on top of the other functions of GST described by the Mining Act 2010.

GST is administered by the Chief Executive Officer (CEO) who is assisted by four Directors of the Geological Services Directorate, National Geo-scientific and Minerals Database Directorate, Laboratory Services and Export Permit Directorate and Business Support Services Directorate. The Directors are assisted by ten Section Managers.

In line with the existing Government Procedures there are four Units operating directly under the CEO and these are Internal Audit, Information, Procurement, Management and Legal Directorate. There is also a Board which monitors performance of GST and provides directives and advises accordingly. At present, GST has 145 staff where 66% are professional and technical staff with different geoscientific specializations in earth sciences. This gives GST a strong human resource base to execute its duties.

Charges for Laboratory Services: https://www.gst.go.tz/charges-for-labolatory-services/

For example: Charges for laboratory services.

Chemical analysis: NOTE: Each sample is considered to weigh not more than 250 grams